Yamaha R 3

inquire about this product

Call us : 09419011012

YAMAHA YZF R 3

The all new Yamaha YZF-R3 mounts a newly developed 321cc, liquid-cooled, 4-stroke, in-line 2-cylinder, fuel-injected engine. With all-new engine and chassis designs, the YZF-R3 sports a solid combination of class-leading power and a lightweight body that achieves high levels of riding performance and styling worthy of the "superbike" moniker. At the same time, it offers the nimbleness and easy-to-use character for daily use as well as riding excitement in a variety of usage scenes. The YZF-R3 Sports Model boasts increased displacement and a lighter yet higher-performance chassis, a winning combination that immediately establishes the model as one of the most competitive entries in its class. The new product offers agile handling from the lightweight body, mass centralization measures, etc. It aims to achieve an excellent balance of both high performance and fuel efficiency and a riding position that is good for sporty riding and results in less rider fatigue.

R 3Engine type 2-cylinder, liquid-cooled, 4-stroke, DOHC, 4-valves Displacement 321cc Bore & Stroke 68.0 mm x 44.1 mm Compression ratio 11.2 : 1 Maximum Power 30.9 kW (42.0PS) @ 10,750 rpm Maximum torque 29.6 Nm (3.0 kg-m) @ 9,000 rpm Lubrication System Wet Sump Clutch type Wet, Multiple Disc Fuel system Fuel Injection Ignition system TCI (transistor controlled ignition) Starter system Electric Transmission system Constant Mesh, 6-speed Final drive Chain

|

Engine

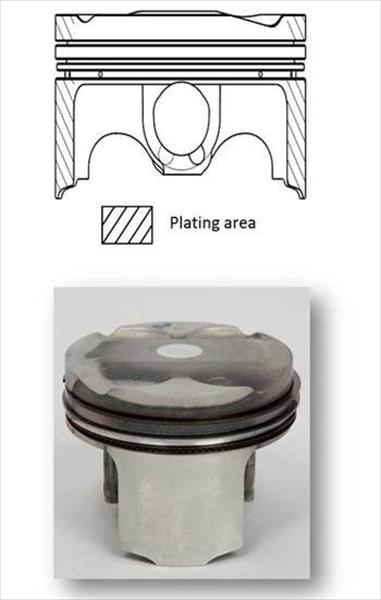

Forged pistons and Diasil cylinders

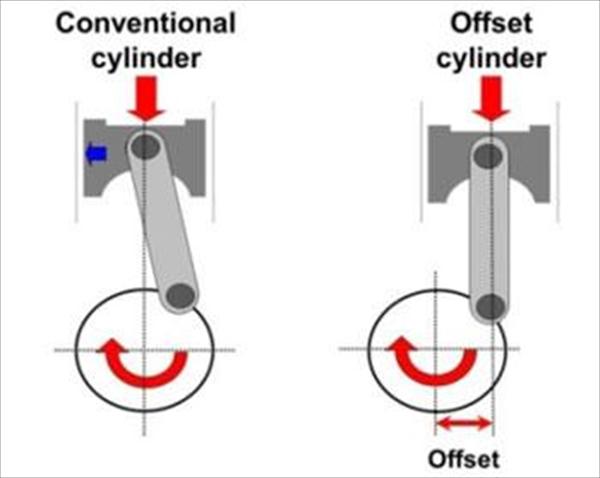

Offset Cylinder

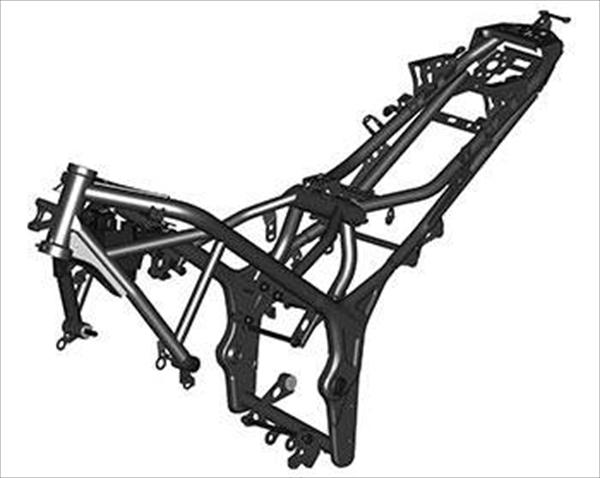

Diamond frame Chassis

Multi-Functional Instrument Panel

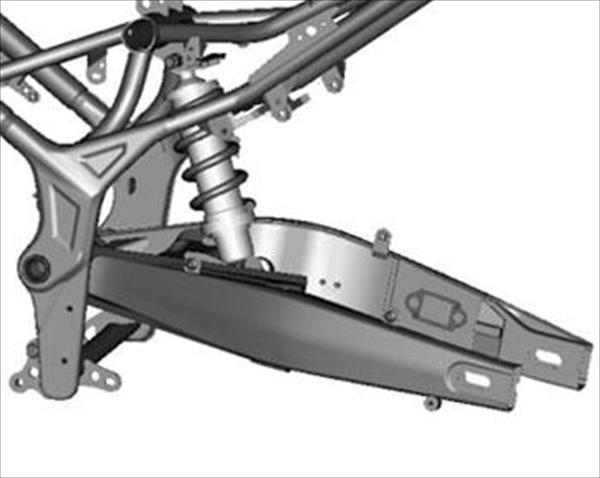

Mono Cross suspension.

Front and Rear disc brakes

Sporty Muffler

Split Headlamps and Air Ducts

TEN-SPOKE CAST ALUMINIUM ALLOY WHEELS

Front Suspension

Racing Blue

Black Lightning

Service Schedule

SERVICE SCHEDULE FOR YZF-R3